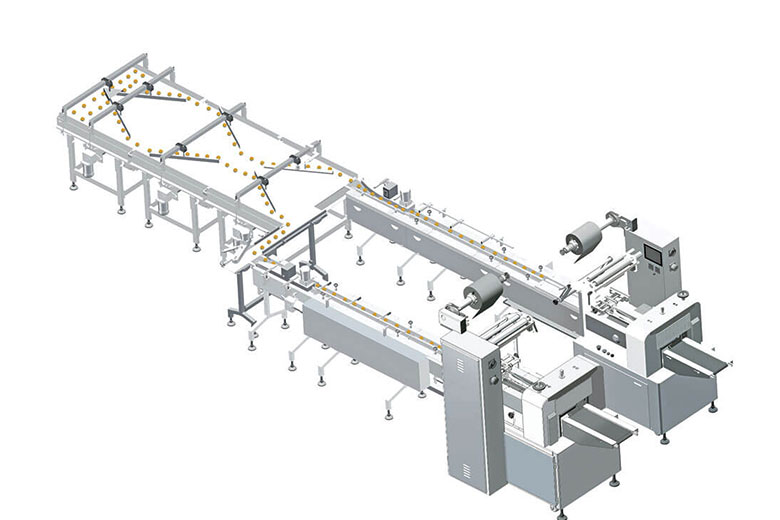

产品介绍 DescriptionCB-420V Fish and Seafood Packaging Machine,

it is controlled by Japan’s Mitsubishi programmable controller, 2310

color touch screen, Mitsubishi servo drive system is used, and all

electrical appliances such as Japan, Europe, and Taiwan are used.

Equipped with complete safety protection measures. Advanced seafood packaging technology with a focus on freshness

Seafood

packaging requires the latest innovations in preservation and hygienic

design to ensure maximum shelf life, attractive appearance and

unquestioned freshness. CHLBpack

offers a full range of advanced automated packaging solutions designed

to produce the most popular formats for fresh, frozen and smoked seafood

customers expect. Choose the right equipment for the packaging

capabilities you need and give your customers the quality they can see. Tray sealers, thermoformers, horizontal and vertical flow wrapping

machines – all of our solutions are designed to give you the packaging

flexibility and versatility you need to produce top-quality applications

at maximum efficiency. Whether you’re opting for gas-flushed MAP to prevent spoilage,

removing air completely to conform to product shape, or preparing

case-ready entrees for supermarket shelves, CHLBpack has the seafood packaging solutions you need. Working with us, you gain access to a wide range of packaging

technologies for the same fresh, frozen, or processed seafood product in

the most attractive varying formats on the market today:

MAP Shrink Vacuum Skin (Protruding, Super Protruding, ISOPACK) Horizontal Form Fill & Seal (HFFS) Vertical Form Fill & Seal (VFFS) Darfresh on Tray And more

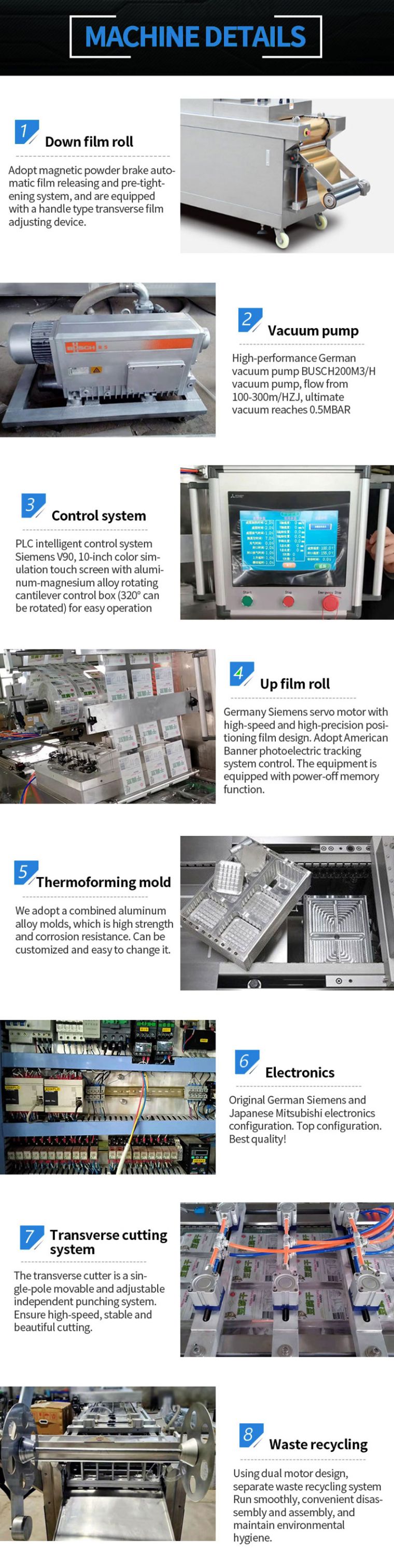

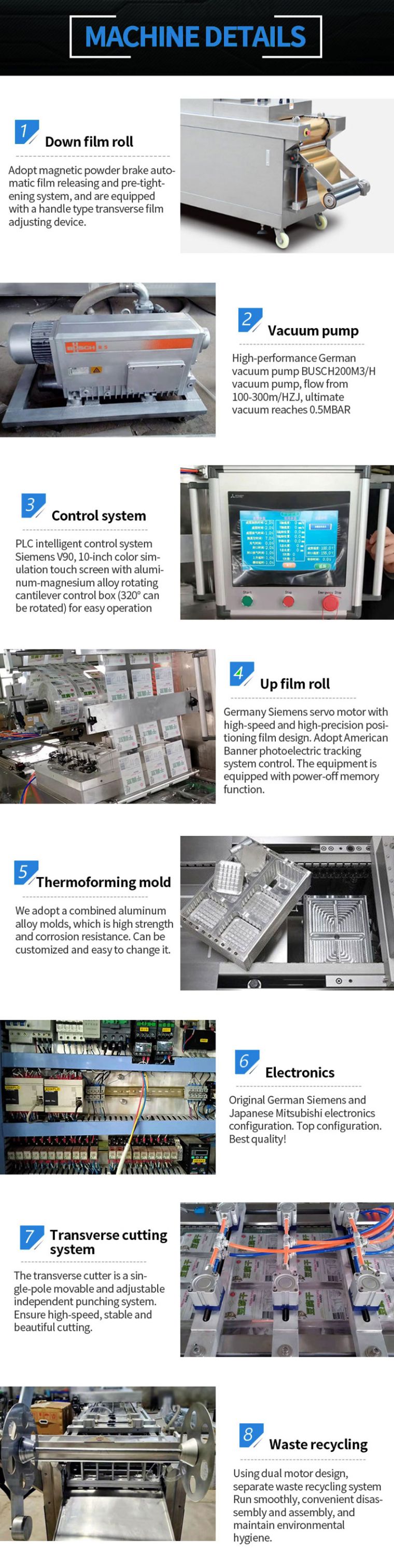

Outstanding FeaturesVersatility: Soft and hard film, multi-step distance, vacuuming, adding nitrogen to make your product fully summarized on one machine. Efficiency: Equipped with a high vacuum vacuum pump imported from Germany, the

working cycle is fast, and the operating cost of labor and equipment

investment is effectively reduced. Safety: The

safety emergency and perfect and seamless protective measures all over

the fuselage make every hidden danger do not exist, and fully feel the

humanization of modern fully automatic machinery. Convenience: The transmission chain is equipped with automatic lubrication, and the

box plate of the body can be easily disassembled, allowing you to face

every part of the machine and the working process intuitively, making

maintenance, maintenance and cleaning more convenient. Strength: The

whole machine is made of 304 food-grade all-stainless steel frame

structure, which will never be deformed; the parts are made of

all-stainless steel standard products, and the molds are carved with

high-strength finished aluminum plates, which is a fine art grades are

assembled. Convenience: The sliding ball transfer in the unloading area of the finished

product ensures that the product will not be injured due to falling.

Connect directly to your automatic transfer overpack system. Advantages: It

has the production technology and technology of the European equipment,

and the domestic can match the advantageous price and all-weather

customer service. CHLBpack

can provide a whole packing solution and integrate fully automated

systems, include Loading, forming, aligning, sealing, cutting, packing,

cartoning – every individual process is linked, ensuring a seamless

transition and flawless production when time matters most and helps

reduce labor costs.

Specification| Model | CB-420V | | Top Film width | ≤422 mm | | Bottom Film width | ≤395 um | | Vacuum Level | ≤200 Mpa | | Single knife packing speed | 4-7 bags/min | | Power | 380 V, 50 HZ, 10 KW | | Outer dimension | L5500xW900xH1750mm(L*W*H) | | Machine weight | 1500KG |

| |

相关产品

|